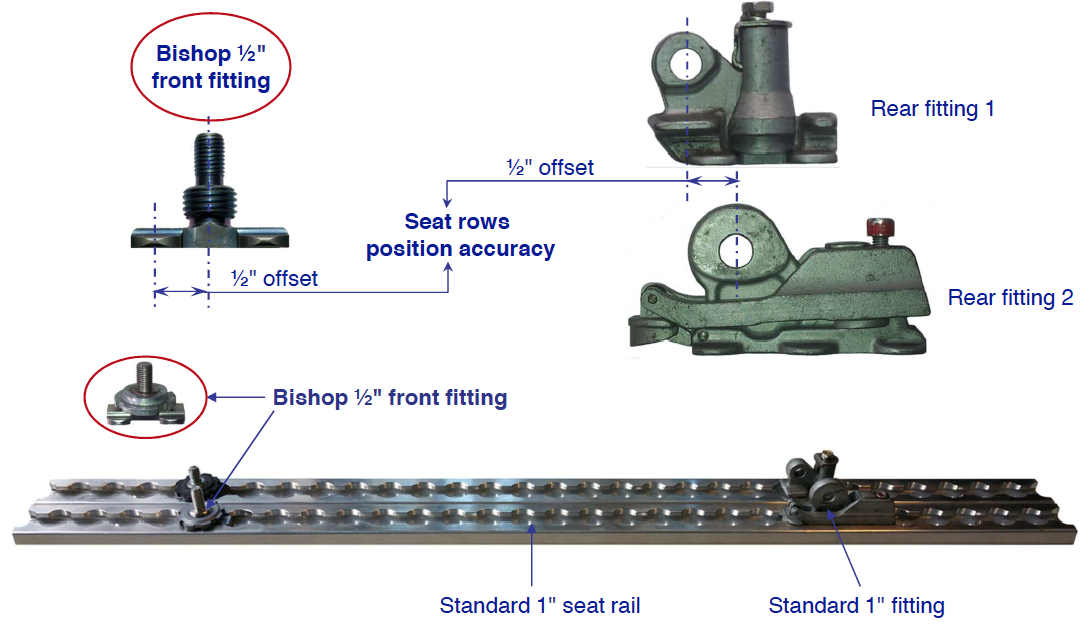

The new ½ inch fitting product has been tested and is ready for the market.

Conversion of 1 inch into 1/2 inch seat rail pitch

- Since the creation of the conventional seat rail for commercial aviation in the early 1930s, no modification of the track has been done with regards to the seat position accuracy.

- The airline industry is still constrained by the predefined track pitch of 1 inch between the seat leg attachment holes.

- Developed by the Bishop GmbH, the conversion of the 1 inch seat rail into ½ inch, and finer seat position accuracy liberates airlines from the 1 inch constraint and gives them the possibility to attach passenger seats with greater flexibility.

- This innovative idea is a definite solution to the non-trivial problem of the air cabin reconfiguration process. Namely the answer to the following question: 1 inch or 2 inch?

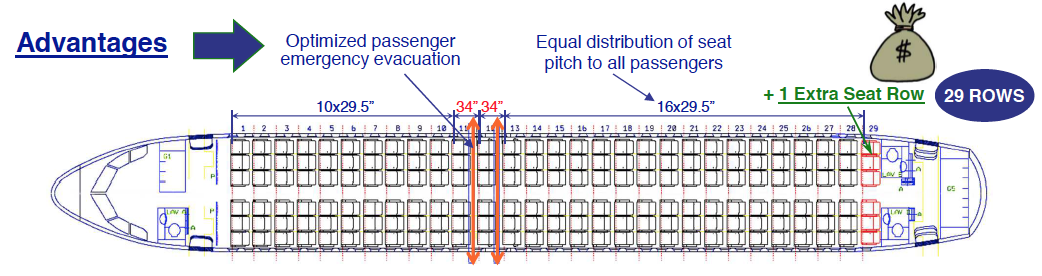

- The seat rail conversion idea allows airlines to fine-tune the position of the cabin seats and monuments, optimise the cabin management, and to install one extra passenger seat row in the air cabin due to this added flexibility.

Optimized A320 Cabin Seat Layout (100% economy class) +1 Extra Seat Row

Why the Bishop conversion idea of the standard 1 inch seat rail pitch?

Answer: Attach your seat rows at the desired position, enhance the passenger comfort and optimize your Net Revenue.

FSAS Flexible Seat Arrangement System

Click on a image to download the PDF file

Airbus Certificate of Approval

AIRCRAFT DESIGN

(4 Seated Turbojet aircraft) This aircraft is a combination of a strengthened French kit aeroplane, The Orion (a piston engine – pusher configuration aircraft) and the Marbore II turbojet. The strengthening comprises of additional longerons, spars, ribs and stringers. The benefits of this modification are not only to produce a high performance aircraft but the installation of the turbojet that will provide advantages in centre of gravity, structural loading and vibration.

Download more Information:

Concept Aircraft Design (PDF – 212KB)

FSAS “Flexible Seat Arrangement System”

FSAS was developed on the basis of the airplane seating system. FSAS fits the standard seat rows in most airplanes, and is controlled by a small, central computer unit. The safety device securing the seat rows is controlled electro-magnetically by a connection with the cabin lights. FSAS enables airline companies a maximum of flexibility, at minimum cost.

Bishop GmbH – Aeronautical Engineers has legally taken out a patent for the brand name of this system (Nr. De 102 II 437 AI).

For further information, see the FSAS registration form.

ASS – AIRCRAFT SECURITY SYSTEMS

(Recent terror attacks have lead to a tightening of airline security regulations. Airplane hi-jacking, ground attacks, bomb attacks and acts of sabotage have confronted the aviation industry with new challenges.

Based on several years of experience with ballistic protection systems and executives, employed in the aircraft industry, at finding an effective solution to this increasingly problematic issue. Bishop GmbH is developing customized (taylormade) protection solutions against different threat scenario for civil aircraft, as well as military applications.

For further information, see the ASS form here.

Ballistic Impact Simulation

An innovative research has recently been conducted at Bishop GmbH into the use of various simulative programs and their ability to model bullet impacts. This research has been undertaken in readiness for proposed more complex research into bullet impacts including “live fire tests” with particular interest on the damage effects caused by bullets impacting on composite materials.

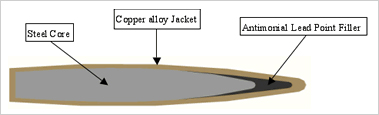

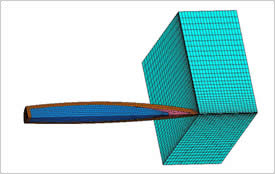

With the use of both ALTAIR HYPERMESH and LS-DYNA a simple model was constructed so as to test the programs abilities of such a simulation. HYPERMESH was used as the pre-processor and LS-DYNA as the processor and post-processor.The simple model that was constructed was that of a .50 Calibre Armour Piercing Bullet with an impact velocity of 600 m/s impacting against a 20mm thick mild steel plate.

.50 Calibre armour piercing bullet

A ¼ 3D model was constructed in which the symmetry conditions were taken advantage of so as to reduce the size of the model and thus the time required to run the simulation.

As this was just a simple simulation the thermal effects were not considered. The shear effects in the simulation also require further work so as to more accurately simulate the bullets behaviour. However both HYPERMESH and LS-DYNA successfully proved their abilities at modelling such a scenario.

Future Work

It is hoped that further work will continue from this brief introduction in that the simple model will be improved so as to more accurately demonstrate the shear and thermal effects as well as the behaviour of a composite material.

Due to security measures, we can only present general information at this point. Within a personal meeting we will be able to provide you with further information to your specific requirements. The Bishop GmbH Company is always interested in special projects and programmes. You may reach us confidentially, at any time.

Phone: +49-40-86 62 58- 10

Fax: +49-40-86 62 58- 20

E-Mail: info@bishop-gmbh.com